getting good lead and the cost is roughly two dollars per pound of pure lead, which goes along way when pouring.

The next step is to decide which molds you like and purchase the mold and hooks. The hook is one of the most important things to me, so I decide on a hook brand, size and thickness and then find a mold that work for those hooks. Do-It Molds is the leader in lead molds and they have good details on their website about which hook size, style and brand will work for each mold you are looking into.

The tools to pour your own lead are a melting pot for the lead and a ladle if you have the smaller melting pots that require you to pour individually. A production style melting pot works great and you can pour much quicker without the need for a ladle. This is where you have to determine your level of interest and how much you will be pouring, but to get started expect to spend $30 to $50 per mold and $40 to $100 for a melting pot.

If you are making a skirted jig, you can purchase skirts ready to go or make your own. It is much cheaper to make your own and the customization is unlimited. Skirt strands, rubber collars and a skirting tool are all you need to make your own skirts.

THE PROCESS

Lead can be dangerous to work with, so always pour in a ventilated area and wear the proper safety equipment. Using a pair of gloves and a having a metal pan nearby will ensure you don’t burn yourself while pouring or melt anything with the finished product.

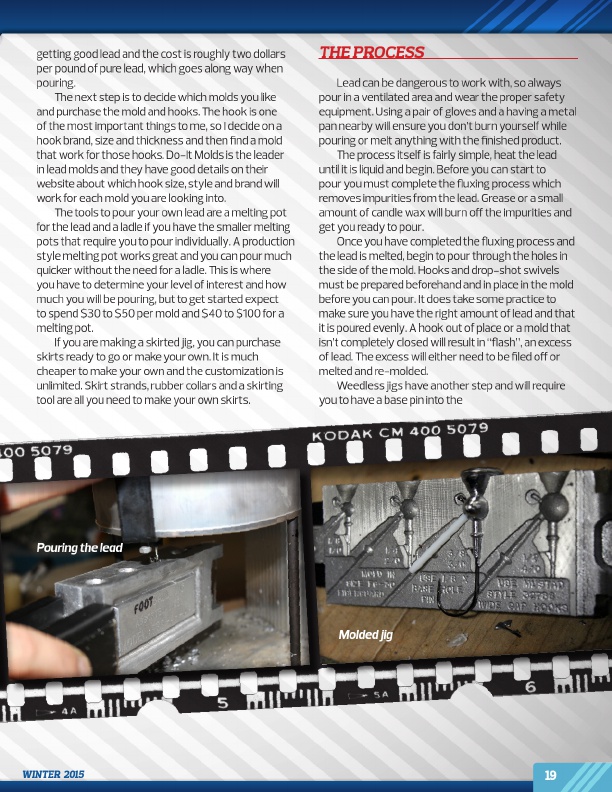

The process itself is fairly simple, heat the lead until it is liquid and begin. Before you can start to pour you must complete the fluxing process which removes impurities from the lead. Grease or a small amount of candle wax will burn off the impurities and get you ready to pour.

Once you have completed the fluxing process and the lead is melted, begin to pour through the holes in the side of the mold. Hooks and drop-shot swivels must be prepared beforehand and in place in the mold before you can pour. It does take some practice to make sure you have the right amount of lead and that it is poured evenly. A hook out of place or a mold that isn’t completely closed will result in “flash”, an excess of lead. The excess will either need to be filed off or melted and re-molded.

Weedless jigs have another step and will require you to have a base pin into the

Pouring the lead

WINTER 2015

Molded jig

19