®

Spring 2021

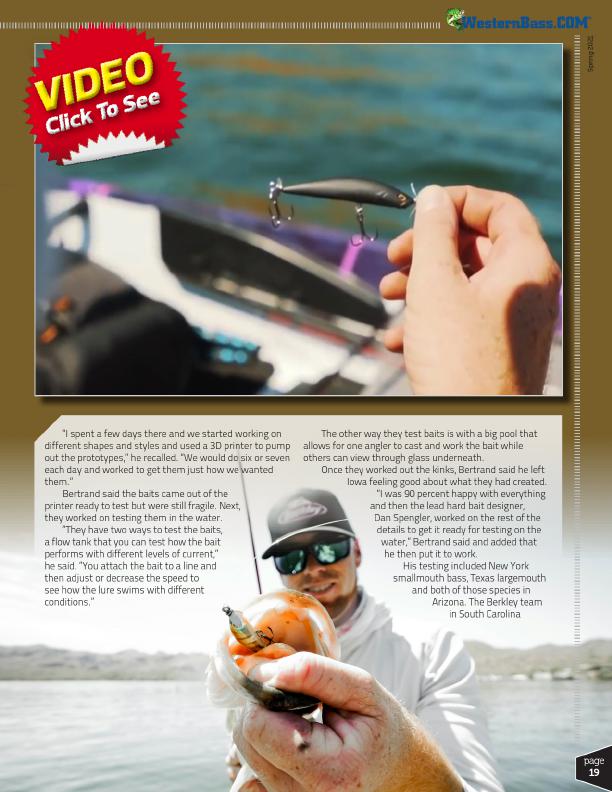

“I spent a few days there and we started working on different shapes and styles and used a 3D printer to pump out the prototypes,” he recalled. “We would do six or seven each day and worked to get them just how we wanted them.”

Bertrand said the baits came out of the printer ready to test but were still fragile. Next, they worked on testing them in the water.

“They have two ways to test the baits, a flow tank that you can test how the bait performs with different levels of current,” he said. “You attach the bait to a line and then adjust or decrease the speed to see how the lure swims with different conditions.”

The other way they test baits is with a big pool that allows for one angler to cast and work the bait while others can view through glass underneath.

Once they worked out the kinks, Bertrand said he left

Iowa feeling good about what they had created.

“I was 90 percent happy with everything

and then the lead hard bait designer,

Dan Spengler, worked on the rest of the

details to get it ready for testing on the

water,” Bertrand said and added that

he then put it to work.

His testing included New York

smallmouth bass, Texas largemouth

and both of those species in

Arizona. The Berkley team

in South Carolina

page

19