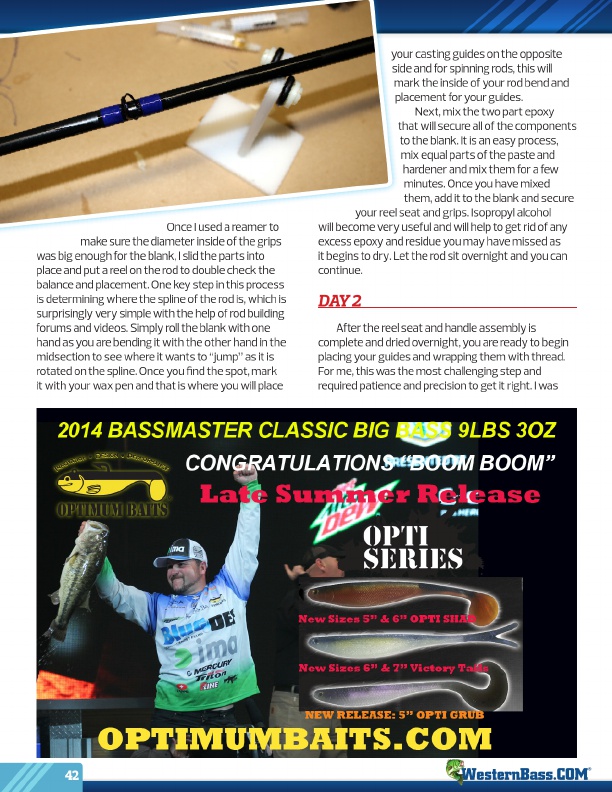

Once I used a reamer to

make sure the diameter inside of the grips was big enough for the blank, I slid the parts into place and put a reel on the rod to double check the balance and placement. One key step in this process is determining where the spline of the rod is, which is surprisingly very simple with the help of rod building forums and videos. Simply roll the blank with one hand as you are bending it with the other hand in the midsection to see where it wants to “jump” as it is rotated on the spline. Once you find the spot, mark it with your wax pen and that is where you will place

your casting guides on the opposite

side and for spinning rods, this will

mark the inside of your rod bend and

placement for your guides.

Next, mix the two part epoxy

that will secure all of the components

to the blank. It is an easy process,

mix equal parts of the paste and

hardener and mix them for a few

minutes. Once you have mixed

them, add it to the blank and secure

your reel seat and grips. Isopropyl alcohol will become very useful and will help to get rid of any excess epoxy and residue you may have missed as it begins to dry. Let the rod sit overnight and you can continue.

DAY 2

After the reel seat and handle assembly is complete and dried overnight, you are ready to begin placing your guides and wrapping them with thread. For me, this was the most challenging step and required patience and precision to get it right. I was

42 ®

http://optimumbaits.com/