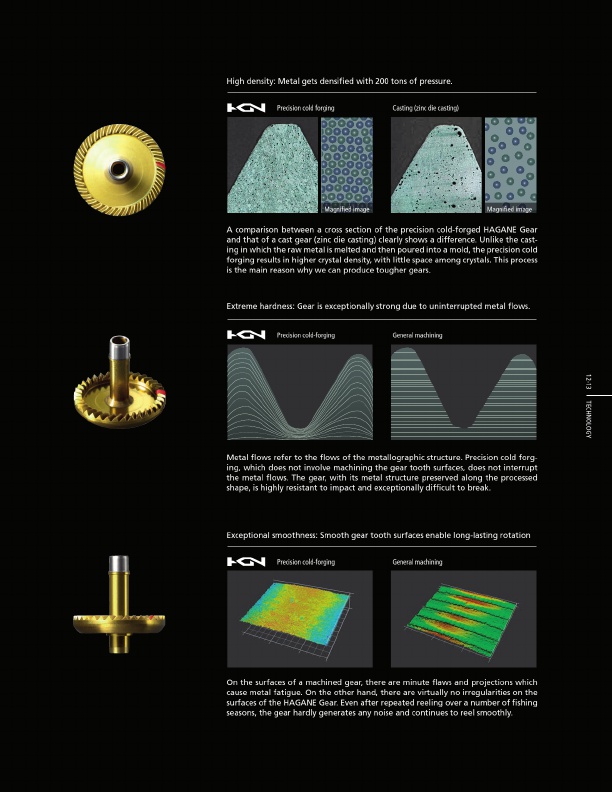

High density: Metal gets densified with 200 tons of pressure.

Precision cold forging

Casting (zinc die casting)

Magnified image

Magnified image

A comparison between a cross section of the precision cold-forged HAGANE Gear and that of a cast gear (zinc die casting) clearly shows a difference. Unlike the cast- ing in which the raw metal is melted and then poured into a mold, the precision cold forging results in higher crystal density, with little space among crystals. This process is the main reason why we can produce tougher gears.

Extreme hardness: Gear is exceptionally strong due to uninterrupted metal flows.

Precision cold-forging

General machining

12-13 TECHNOLOGY

Metal flows refer to the flows of the metallographic structure. Precision cold forg- ing, which does not involve machining the gear tooth surfaces, does not interrupt the metal flows. The gear, with its metal structure preserved along the processed shape, is highly resistant to impact and exceptionally difficult to break.

Exceptional smoothness: Smooth gear tooth surfaces enable long-lasting rotation

Precision cold-forging

General machining

On the surfaces of a machined gear, there are minute flaws and projections which cause metal fatigue. On the other hand, there are virtually no irregularities on the surfaces of the HAGANE Gear. Even after repeated reeling over a number of fishing seasons, the gear hardly generates any noise and continues to reel smoothly.